ইমেল বিন্যাস ত্রুটি

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

খবর

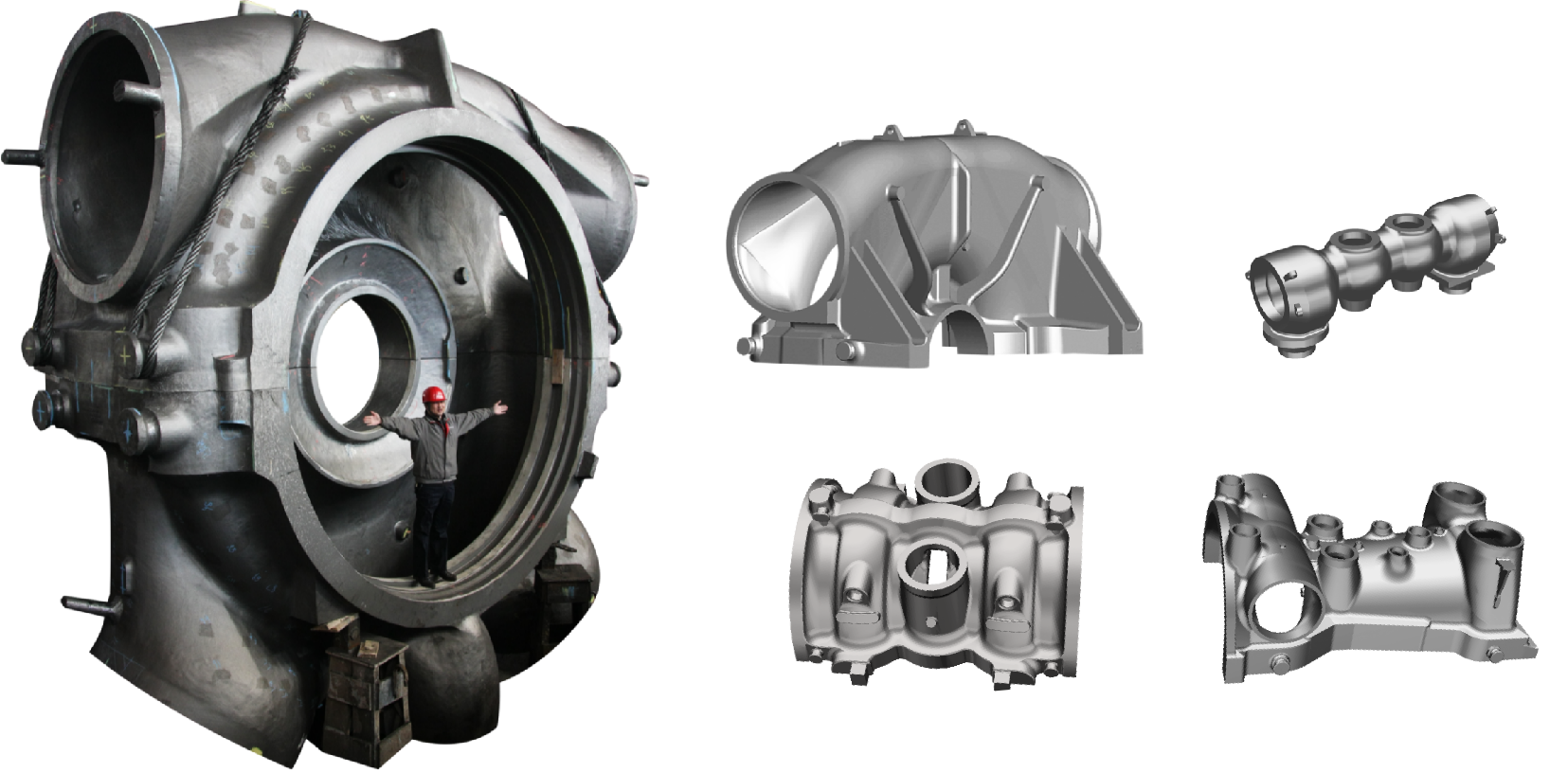

Why do Your Gravity Castings always Blacken?

The gravity casting machine is also called an aluminum alloy gravity casting machine because it is always used in the production of aluminum alloy castings. There will always be manufacturers wondering why the aluminum castings I produce are always blackened.

As an active metal, aluminum is easy to oxidize and blacken when it reaches a certain temperature and humidity. Therefore, during the production of the gravity casting machines, attention should be paid to the subsequent treatment of castings.

Manufacturers should pay attention to effectively controlling the casting speed and time in the production process of gravity casting. After the production of aluminum castings is completed, they should pay attention to timely cleaning the surface of aluminum castings. If the cleaning is not complete, it may accelerate the blackening of aluminum castings. Employees who produce castings should pay attention to wearing gloves to avoid direct skin contact with aluminum castings. After the production of castings, they should pay attention to drying.

After the production of aluminum castings by gravity casting machine, attention should be paid to the placement environment of aluminum castings. Aluminum castings should be placed in a ventilated and dry environment to avoid direct sunlight. As long as the aluminum casting reaches the temperature and humidity it can't bear, the aluminum casting won't turn black so easily.

Do you know the cause of casting deformation of the gravity casting machines?

The casting deformation is the result of gravity casting stress. If the casting stress produced during the cooling process exceeds the yield strength of the alloy at this temperature, residual deformation will occur; If the tensile strength is exceeded, cracks will be formed; If it shows residual stress within the range of elastic strength, the design strength may be changed, and even the castings may be deformed or cracked during storage or use. In short, the gravity casting machine gives the casting a force that it can't bear during production, so the casting can't bear so it deforms.

However, the casting deformation caused by steel, non-ferrous metals, ductile iron, and even some gray iron can be corrected by mechanical methods, during heating or heat treatment. In production, we should try our best to make the structure of castings reasonable. The use of reverse deformation in the production of gravity casting mold can appropriately control the generation of casting stress, to avoid casting deformation as much as possible.

The quality of casting products will also be affected by the quality of gravity casting mold

In the selection of gravity casting machines, everyone will choose good equipment, because everyone knows that the quality of the equipment will affect the quality of products, and the quality of products produced by good equipment will be better. But the mold also plays an important role in casting, for example, in the production of aluminum alloy auto parts, the accuracy and durability of gravity casting mold have a great impact on the casting.

Due to the low melting point and good casting performance of aluminum alloy, gravity casting castings are generally formed directly by molds in mass production, such as aluminum alloy cylinder blocks and cylinder heads of the engine. This can not only improve the production efficiency of castings but also control the microstructure and grain size of castings and improve the quality of castings by adjusting the temperature distribution in different parts of the mold.

Aluminum alloy gravity casting molds vary with the complexity of casting shapes. Even if the same casting products may adopt different casting processes, the molds required for casting products may also be different. But no matter what kind of gravity casting products are produced, the quality of the molds used is better, so the quality of the products produced will be good.

For more information about counter gravity casting, gravity casting parts, gravity die casting parts, plz feel free to contact us.