ইমেল বিন্যাস ত্রুটি

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

খবর

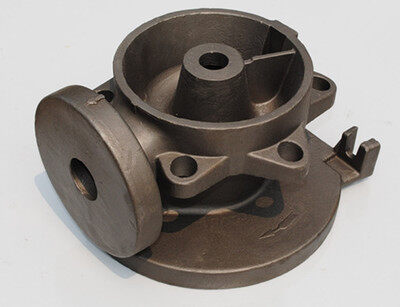

Quality Problems Encountered in Nodular Cast Iron Casting Production

General rules affecting shrinkage porosity of ductile iron

Modulus of ductile iron castings. The modulus of the casting is greater than 2.5, so it is easy to realize riser-free casting, but some experts have doubts about the limit value. Generally speaking, thick and large castings are easy to cast nonshrinkage castings due to graphitization and expansion. At this time, the carbon equivalent shall not be greater than 4.5% to avoid graphite floating. Thin and small castings with dispersed hot spots are easy to produce shrinkage porosity, which can be solved by setting chills, chrome ore, or local internal risers. Special attention should be paid to the feeding of the gating and riser system. Generally speaking, hot risers should be used as far as possible to avoid the use of cold risers.

Pay full attention to the rigidity of the sandbox and the hardness of the sand mold. In terms of the stiffness of the sandbox and the compactness of the sand mold, the setting cannot be too sufficient.

The rationality of pouring and riser process design. Try to use hot risers and chill, and the feeding effect of cold risers is very poor.

The cooling rate of mold

Reasonable selection of pouring temperature and pouring speed. For some thicker castings, it can be considered to appropriately increase the pouring temperature and prolong the pouring speed to solve the shrinkage porosity. At the same time, it is beneficial for the secondary oxidation slag to float out of the casting and increase the qualification of flaw detection.

Reasonable selection of chemical composition and appropriate residual magnesium and rare earth content

Under the condition of sand mold cooling, striving for more graphite balls is beneficial to reducing shrinkage porosity and improving mechanical properties.

For better raw materials and good metallurgical quality of molten iron, special attention should be paid not to keep molten iron at a high temperature for too long before being discharged. At the same time, pre-treatment should be done to increase the graphite crystal core of molten iron before being discharged, to improve the number of graphite balls, and reduce shrinkage porosity.

A new view of reducing shrinkage

The composition of ductile iron is selected near the eutectic point, and the fluidity of molten iron is the best, so the molten iron is easy to supplement and shrink during solidification.

The sulfur content of nodular iron should not change too much before and after modularization. That is, the sulfur content of raw hot metal should not be too high. With high sulfur content, graphite is easy to precipitate early. It is easy to shrink and loosen.

During the solidification of ductile iron, the graphite expansion time is controlled to delay the graphitization expansion. When the choice of carbon equivalent is determined, high carbon and low silicon. An appropriate amount of residual magnesium, correct inoculation, and pay attention to the final flow inoculation.

Pay attention to the rapid smelting of molten iron, avoid keeping it in the furnace for too long at the tapping temperature, and avoid excessive smelting and insulation temperature of more than 1550 degrees, resulting in the loss of a large amount of carbon and crystal core. Generally, it needs to be reprocessed after about 10-20 minutes. Even after various inoculation treatments, this molten iron will produce carbides and shrinkage porosity, which is difficult to eliminate.

After the hot metal is spheroidized, it should be poured immediately. It is strictly forbidden to wait too long to cause the spheroidization to decay.

Using the nebulizer containing lanthanum and rare earth, the graphite crystallizes less at the initial stage of solidification, avoiding the appearance of individual large graphite balls. The number of graphite balls is relatively large, and the size is relatively uniform, indicating that the precipitation time of graphite balls is relatively consistent during solidification, and the expansion is large in the later stage of solidification. At the recent meeting of Wuhan Huazhong University of science and technology of the Casting Association, the engineers of Jiangyin Jixin proposed that this kind of spheroidizing agent use process has no effect on the thick and large cross-section wind power ductile iron and is not applicable.

The larger the carbon equivalent of ductile iron is, the wider the crystallization and solidification range is, and the larger the solid-liquid coexistence range is. During the solidification process, the flow of liquid iron is affected by primary dendrites, which hinders the flow and feeding, and it is easy to form shrinkage porosity. At the same time, the high silicon content in the molten iron is easy to promote the nucleation and growth of graphite prematurely. At this time, the graphitization expansion is in the solid-liquid coexistence period, which is unfavorable to the reduction of shrinkage porosity. Therefore, it is of great significance to solve the shrinkage and porosity of ductile iron castings in the practical casting technology work to delay the graphitization expansion through the above-mentioned process measures.

Searching for individual cast iron skillets, smith and nobel cast iron, windmill cast iron manufacturer from China, you can get high-quality products at a nice price.